New-look offshore wind construction concept floated to uncork looming US bottleneck

'Feederdock' system, which uses a U-shaped crane vessel that docks-in tug barges shuttling turbine components out from coastal yards, will be '25-30% faster' than traditional installation vessels, say its developers

An innovative offshore wind farm construction concept has been launched today (Monday) by ONP Management and Renewable Resources International (RRI) to help answer the looming installation vessel bottleneck being faced by developers building the first gigawatts of projects in the US Atlantic.

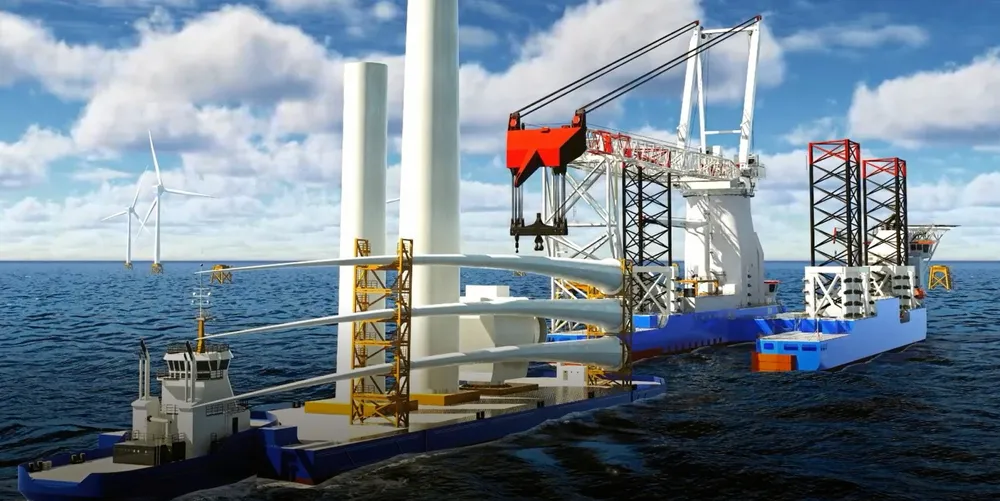

The so-called Feederdock – which is based around a U-shaped crane vessel that can dock tug barges shuttling jacket, blades and nacelles from coastal yards out to site, creating a ‘fixed-to-fixed’ installation process that avoid issues involving floating barges offloading components to a jack-up – is expected to be “25-30% faster” than competing feeder solutions, installing up to three ultra-large turbines every two days.

Featuring a 3,000-tonne crane with a maximum hook height of 182 metres, the jack-up has been engineered by European marine contracting heavyweight Tractebel Overdick to handle componentry for turbines as large as 25MW in waters as deep as 70 metres. The tug barges are designed to be built in America, in keeping with the Jones Act which requires all vessels moving between US ports be US-flagged and -crewed.

“We aim to have it ready for 2026 as that’s when the really big wave of construction is going to hit [off the US east coast]. And it will be totally port-independent, that is, whether the tug barges have to pass under bridges or not, it is an efficient solution, we believe 25-30% faster than other concepts.”

“The concept also can support a local supply chain: with this solution, tug barges could travel up the Hudson River [in New York state], for example, and collect components from various suppliers and then transporting them out to a big coastal port for staging and assembly. This all provides a tremendous flexibility for developer, we believe,” said Geissbuhler.

ONP Management and RRI have secured shipyard capacity to build a first Feederdock flotilla, which will be operated by Harren group-owned Atheleon, inside four years. The concept’s development is being financially backed by unnamed “US-based global asset manager”.

“This solution allows for the possibility of having all your componentry in different places but all being shuttled in an efficient way to the jack-up which is just constantly installing. A much better use of time in general,” said Geissbuhler.

“All our lessons learned have been incorporated into the Feederdock design and are constantly being benchmarked with the industry.”

The American Bureau of Shipping is “accompanying” the project to review and class the vessel in the run-up to launch, having awarded the concept with its key ‘approval in principle’ in 2020.

Geissbuhler said: “There is a general understanding that the industry has to move quickly to feeder solutions [because of the lack of WTIVs] but the solutions that are currently anticipated in the market have the massive disadvantage when it comes to the actual transfer of the components at sea, floating barge to jack-up – risky, complicated and time-consuming. Our solutions prevents this from being an issue.”

The US Biden administration last year set out the “national goal” of having 30GW of offshore wind plant operational by 2030 but the industry has been presented with monumental task in reaching this target due to factors including having a near-nonexistent sector supply chain, an ageing onshore power grid, and running battles with other ocean-operating industries, chiefly the fisheries sector.

(Copyright)