ABS 'approves in principle' US startup's jack-up installation system promising 50% cost savings

Houston-based CLS Wind's technology has smaller footprint and simpler mechanics that will enable speedier wind deployment with 75% lower emissions

Renewable energy startup CLS Wind earned 'approval in principle' (AIP) by classification body American Bureau of Shipping (ABS) for its innovative installation system that is says will slash costs by up to 50% for onshore, offshore, and floating wind sectors while enabling ever larger turbines.

“This is an exciting milestone for CLS Wind and domestic renewable energy production,” said Rob Langford, ABS vice president for global offshore renewables. ABS completed design reviews based on class and statutory requirements.

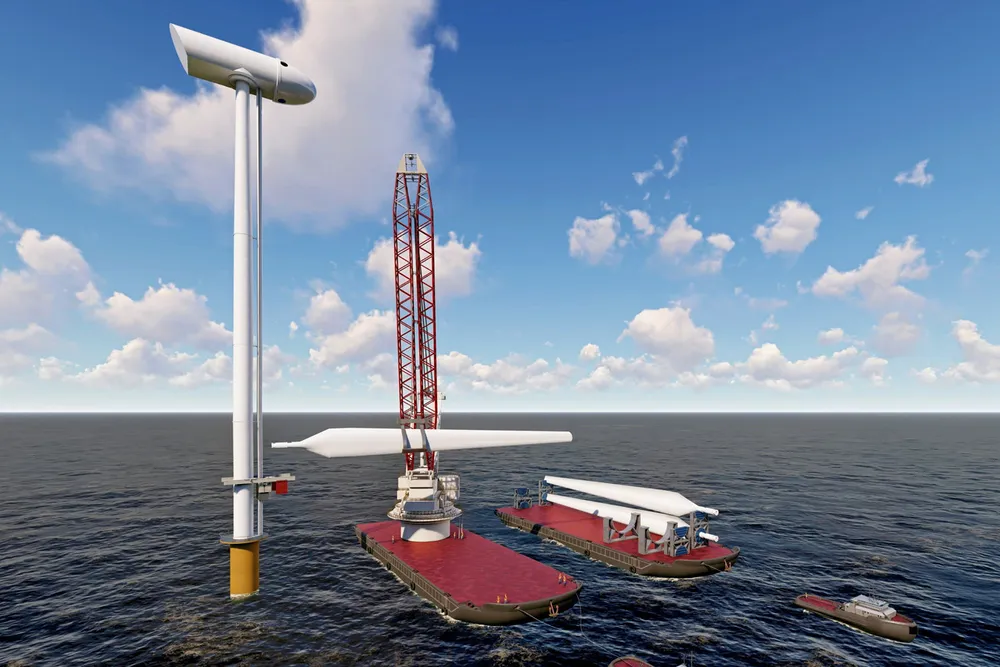

The patented elevator style assembly system promises easier, safer and faster wind turbine and nacelle installation and maintenance, without the use of large cranes and heavy-lift barges or vessels, ABS said.

The Houston-based company, founded by engineers Kent Johnson and Andres Garcia with long track records in big machinery R&D for American OEMs, developed the system that foregoes the use of large cranes to lift heavy components high overhead.

CLS’ jacking system instead rests on the foundation or ground pad and runs alongside the tower, raising components like an elevator.

“Because the wind turbine components are loaded to the CLS platform at a lower height, instead of being lifted to the component's final installation height, we can use a smaller crane,” said Garcia, CLS’ chief technology officer.

“Instead of having to use a 1000-tonne crane, we can use a 300-tonne crane to achieve the same component installation,” he said.

The machinery is also far simpler than conventional cranes.

For onshore wind, a crane capable of lifting a 300-tonne, 5MW nacelle to the top of a 90-metre tower requires at least 69 truckloads of components and large outlays for road and site construction in rural areas. The crane will likely be moved multiple times during installation, requiring it to be dissembled and reassembled each time.

The offshore sector meanwhile faces shortages of heavy lift vessels capable of handling increasingly large and heavy nacelles, with the new standard of 15MW weighing in at some 800 tonnes.

Jones Act complications

“We already found some Jones Act qualified vessels that could do the job” with this system, said Johnson, CLS’ chief executive.

The company also promises its system is applicable to floating systems and can be deployed for both installation, maintenance, and repowering, enabling speedier and more efficient deployment at 75% lower carbon emissions.

CLS has kept its technology under wraps until completing both the ABS AIP certification and 40-foot (12-metre) prototype, was completed and is now getting set to build a full-scale unit.

(Copyright)