Diving offshore wind farm repair robot 'mothership' heads out for sea trials

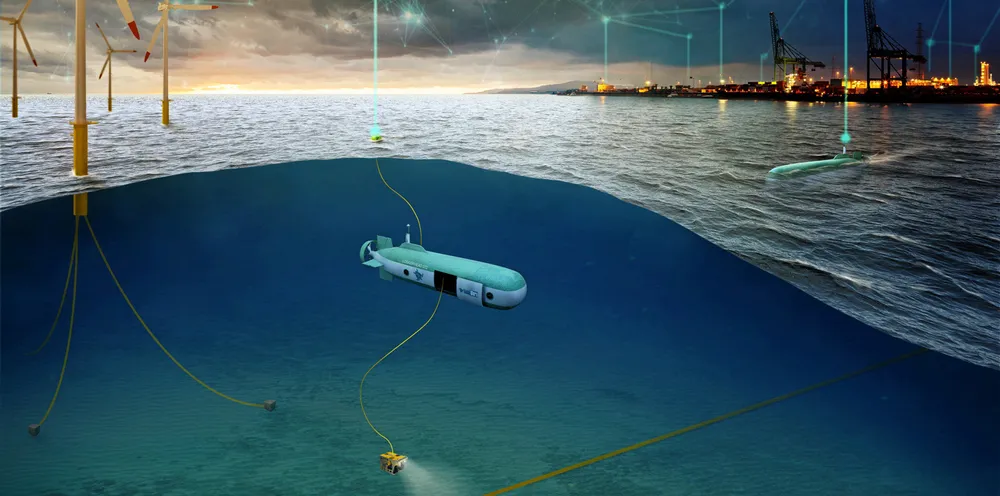

An autonomous diving ‘mothership’ that is designed to transport industrial-scale robots out to offshore wind farms for underwater operations and maintenance (O&M) work has moved closer to commercial launch with plans by Aberdeen technology developer HonuWorx and the Offshore Renewable Energy (ORE) Catapult for an at-sea demonstration of the technology.

The project, funded by Innovate UK, will develop Ridley, a ‘platform’ that would be able to shuttle out remote operated vehicles (ROVs) and bigger-brother autonomous underwater vehicles (AUVs) for offshore assignments, is the next step in the contractor’s disruptive Loggerhead concept, a mobile power and communications hub for offshore robots

The technology is seen by ORE Catapult as “resolving one of the remaining barriers to adoption of subsea robotics by the offshore wind industry in terms of cost, carbon footprint, battery life at sea and digital connectivity”.

Until now, ROVs used for offshore wind farms rarely log more than 50% utilisation as they are reliant upon large, fully-crewed diesel-powered vessels for transportation, with a 21-day inspection mission cost up to £1.5m ($1.35m) and emitting more than 500 tonnes of CO2.

Ferrying ROVs to site in a lightweight, autonomous submersible removes much of financial and environmental cost, of the operation, said HonuWorx, and because the platform submerges to deploy subsea robots without need of crane drops, deployment can be carried out in rough weather without stress on the robot’s sensors and tooling.

“The offshore wind industry recognises that robotics and automation are key technologies to ensure decades of continued growth for the sector: sending people to ever more remote and deep-water sites will become progressively more difficult and expensive,” said Ben George, ORE Catapult’s O&M Centre of Excellence general manager.

“Cost reduction, safety improvement and operational integration: those three challenges are driving technology development in offshore wind operations and maintenance. That’s why this project is so significant: it addresses those factors head on, while also aligning with our own priorities around accelerating robotic, sustainable and smart technologies in the sector.”

(Copyright)